(Auszug aus der Pressemitteilung)

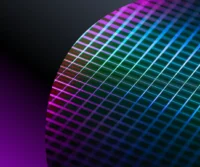

Micron Technology, Inc. (Nasdaq: MU) broke ground today on an advanced wafer fabrication facility located within the company’s existing NAND manufacturing complex in Singapore. This new facility represents a planned investment of approximately US $24 billion (SG $31 billion) over 10 years and is designed to ultimately provide 700,000 square feet of cleanroom space. Wafer output is scheduled to begin in the second half of calendar 2028, helping Micron address growing market demand for NAND technology driven by the rapid expansion of AI and data-centric applications.

The groundbreaking ceremony for this facility, Singapore’s first double-story wafer manufacturing fab, was marked by the attendance of Gan Kim Yong, deputy prime minister and minister for Trade and Industry of Singapore, Dr Beh Swan Gin, permanent secretary of the Ministry of Trade and Industry, Jermaine Loy, managing director of the Singapore Economic Development Board (EDB) and Jacqueline Poh, CEO of JTC Corporation.

“Micron’s leadership in advanced memory and storage is enabling the AI-driven transformation reshaping the global economy,” said Manish Bhatia, executive vice president of global operations at Micron Technology. “We are grateful for the longstanding support and successful partnership with the Singapore government, including EDB and JTC. This investment underscores Micron’s long-term commitment to Singapore as an important hub in our global manufacturing network, enhancing supply chain resiliency and fostering a vibrant ecosystem for innovation.”

This new fab will become an integral part of Micron’s NAND Center of Excellence in Singapore. The facility provides the essential capacity to support continued technology transitions, positioning Micron to meet long-term demand for advanced storage solutions. Additionally, co-locating R&D with manufacturing improves efficiencies, accelerates time-to-market and deepens research partnerships between industry and academia.

Micron’s previously announced high-bandwidth memory (HBM) advanced packaging facility, also located in the same Singapore manufacturing complex, is on track to contribute meaningfully to Micron’s HBM supply in calendar year 2027. As HBM becomes a part of Micron’s Singapore manufacturing footprint, the company expects opportunities for synergies between NAND and DRAM production. Micron will maintain flexibility in managing the pace of capacity ramps in the new facility to align with market demand.

Micron’s advanced wafer fabrication facility investment will create around 1,600 jobs. Combined with the previously announced 1,400 jobs from the HBM advanced packaging facility, Micron’s expansion will support about 3,000 new Micron jobs total. These positions will focus on fab engineering and operations, integrating AI, advanced robotics and smart manufacturing technologies to enhance efficiency and innovation.

“Micron’s latest expansion will strengthen our semiconductor ecosystem and further anchor Singapore as a critical node in the global semiconductor supply chain,” said Jermaine Loy, managing director of the Singapore EDB. “This investment rides on growth in AI and will provide good jobs for Singaporeans. Micron’s advanced facility will leverage advanced robotic automation and boost our advanced manufacturing ecosystem, helping our workforce seize new opportunities.”

The fab will comply with the company’s sustainability commitments and build on the site’s recognition as both a World Economic Forum Sustainability Lighthouse and an Energy Efficiency National Partnership (EENP) Award recipient. The fab will also adhere to LEED standards, such as greenhouse gas abatement, water recycling and waste circularity.

In collaboration with academia and ecosystem partners, Micron’s investment creates opportunities to build a future-ready semiconductor workforce through multiple pathways, offering real-world learning experiences such as internships for students, upskilling the current workforce in AI and smart manufacturing, and advancing R&D talent development to drive future innovation.

Neueste Kommentare

27. Januar 2026

27. Januar 2026

27. Januar 2026

24. Januar 2026

21. Januar 2026

20. Januar 2026